As part of a broad research project, researchers at the German research institute are investigating how to reduce silver consumption in heterojunction photovoltaic devices. The institute has recently succeeded in producing a heterojunction cell with a silver consumption of only 1.4 mg/W.

In a research project funded by the German Federal Ministry for Economic Affairs and Climate Action, the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) is working with several industrial partners to develop innovative solutions to significantly reduce the silver consumption in silicon heterojunction (HJT) cells.

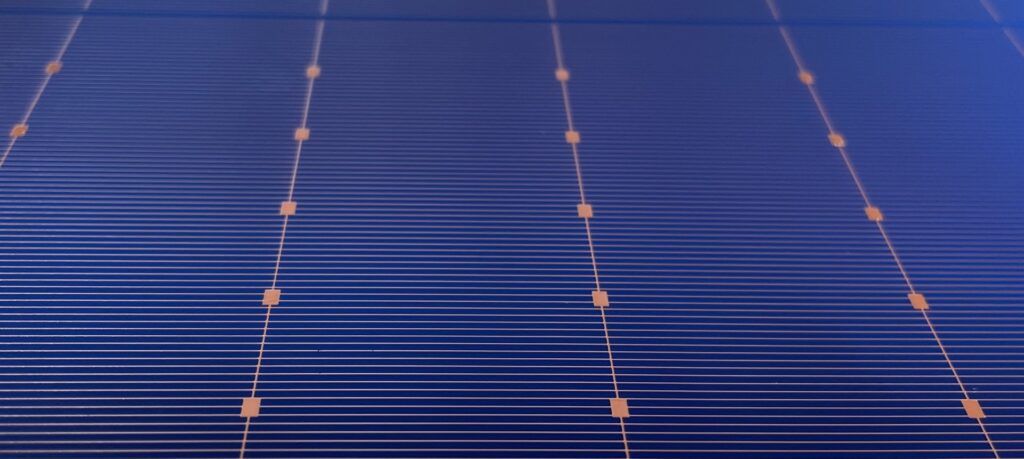

“In this work, the Fraunhofer ISE team investigated various heterojunction cell metallization schemes by using screen-printed silver-copper composite pastes and pure copper pastes in silicon heterojunction solar cells,” Andreas Lorenz, who led the research project, told pv magazine. “Our goal was to significantly reduce the silver consumption while achieving high conversion efficiency by ensuring very good optical and electrical properties of the screen-printed metallization.”

Lorenz said that the following conditions must be met to achieve this goal: use low-silver content paste to achieve ultra-fine grid lines, especially on the front of the battery; use pure copper paste on the back of the battery to significantly reduce or even completely replace pure silver paste.

“To achieve this ultra-fine grid line in screen printing, a new screen structure with ultra-fine mesh is beneficial for achieving ultra-fine and uniform contact,” he said. “We established a model to calculate, compare and optimize the effective silver utilization under different screen structures. The results show that the silver utilization can be doubled by using a silver-copper composite metallization paste with a new screen structure instead of pure silver paste.”

Using the GridMaster simulation tool developed by Fraunhofer ISE, the researchers conducted a series of simulations on different metallization schemes to develop solar cells with high conversion efficiency and low silver consumption. The experiments showed that the traditional front and back pure silver paste metallization process can be gradually replaced by silver-copper composite paste (front) and pure copper paste (back), as well as the use of new ultra-fine mesh (opening size as low as 13 microns) provided by Japanese woven wire mesh supplier Asada Mesh, Co. Ltd. to achieve ultra-fine grid metallization.

“By using the optimal combination of a silver-copper composite paste on the front side and a pure copper paste on the back side, combined with an optimized fine-line printing process, we are able to produce a highly efficient heterojunction cell with a silver consumption of only 1.4 mg/W,” said Lorenz. “This means that even the long-term goal of a silver consumption of less than 2 mg/W has been successfully demonstrated for the first time.”

The study also found that the efficiency of these solar cells is even higher than that of reference cells with pure silver metallization, and the silver consumption is minimal. “The cells with silver-copper/pure copper metallization process have a relative efficiency improvement of 0.9%, “said Sebastian Pingel, a researcher at Fraunhofer ISE. “We achieved this result by optimizing the front gridline opening from 20 microns to 17 microns when printing finer gridlines, while replacing pure silver paste with silver-copper composite paste on the front and pure silver paste with pure copper paste on the back.”

“Unfortunately, we haven’t calculated it for a specific cell yet,” Lorenza said when asked about the room for optimization in manufacturing costs. “It’s possible, but it’s difficult because we need to look at the entire production process to conduct a reliable COO analysis. However, since silver paste costs account for a large proportion of the total cost, the potential for cost reduction will be considerable.”

He concluded, “The next steps for the Fraunhofer ISE research team will focus on two major directions: further reducing the width of the printed grid lines and evaluating the reliability and long-term stability of the new metallization scheme in the components.”

Recently, the research team also demonstrated how to reduce the silver consumption of silicon heterojunction cells by screen printing with low-temperature pastes based on pure silver, silver-plated copper or pure copper. They have published a paper titled “Transition from silver-based to copper-based screen-printed silicon heterojunction solar cells” in the journal Solar Energy Materials and Solar Cells, describing their research results.

Leave A Comment